| Cutting Length: | No Limit | Size: | 770*510*450mm |

|---|---|---|---|

| Machinery: | SMT Machinery | Application: | All Type PCB |

| Weight: | 130 Kg | Guarrantee: | One Year |

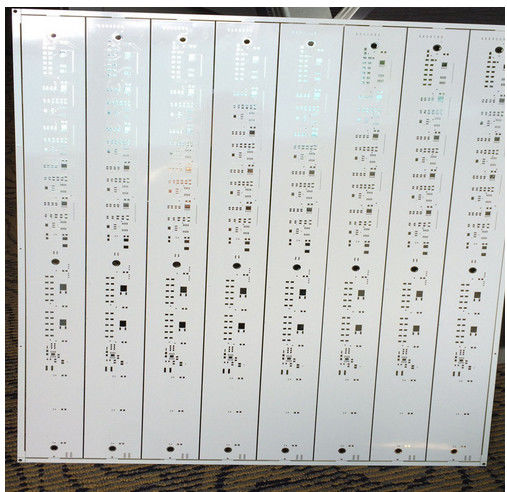

PCB separator For SMT Machinery With No Limit Cutting Length For PCB Length

V Groove pcb depanelizer machine features:

1. Unlike Friction type cutting, No metal remains from the cutting knives.

2. Rurable blade,donot need to sharp many time.

3. It will not damage parts that are 0.3mm distance to V-cut,. Highest components near the v groove of PCB can be up to 60mm.

4. Guillotine style cutting,finish cutting to the PCB

5. Easy operation, no security problems.

6. Cutting speed is 1s / 1 cut, countrolled by foot pneumatic switch.

7. It can cut PCB of any length, small stress, no cutting deformation.

8. Electropneumatic design. Two blades cut, specially for seperating sophisticated thin Aluminum PCB

9. Guillotine type working mode, appliable for PCB of any thickness.

10. No motor drive, the machine wont's be warm.

Air Driven PCB Depanelizer features

1. Gap for insertion of PCB can be easy to adjust by the adjusting knob in front of the machine.

2. Pneumatically driven and electromagnetic valve control.

3. Shearing process without vibrations due to pneumatic drive unit .

4. Shearing PCBs with sensitive SMD, capacitors or thin board even to 0.3mm can be sheared safely.

Our PCB Depanelizer Service

|

1. Engineers available to service machinery oversea |

|

2. Mature technique & forerunner to process makes high quality machinery |

|

3. Effective customer service |

|

4. One year warranty for the machines except accessories |

1. because of the multiple cutting, cutting process is very smooth and greatly improves the capability of position of V-CUT groove .

Even if with shallow slot V-CUT groove the board won t jump out of blade, avoiding adverse.

2. Because cutting force of the blade is small. abd with high speed steel material which is imported from the Swedish. durability of the blade greatly improved , and the lifetime can be one year or more when cutting the aluminum board.

3. All the cutting blades are calibrated by Excitation double-frequency laser interference measurement instrument. Ensure that the latter knife can accurately continue to cut in the slots which already cut by the former knife.The jitter of knife point is less than 0.02mm. Ensure perfect cutting quality.

ASCEN technology co.,ltd specializing in the SMT automatic equipment and provide the automatic solution for the smart factory for save more producing cost.

Whether you'd like to get more info on what,why and how we do what we do, need help with what you're creating,would line to partner up or just say hi!

—--- We'd love to hear from you.

Note : Your information detail will not be published. Required fields are marked*